|

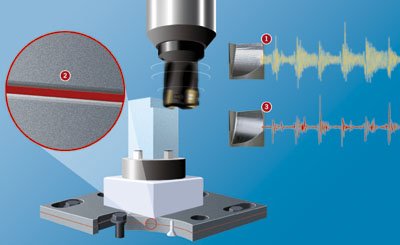

The picture show a graphic of an innovation wich enhances the quality

and shortens the working time when milling in metal.

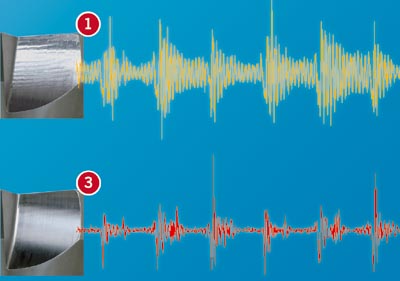

Dot #1 All mechanical work

on metal (drilling, milling) brings vibrations to the work piece. These

vibrations makes it harder to achieve a high surface quality.

Also, the vibrations wear down the tool faster, which brings a need to

change the knives in the tool more frequently.

Dot #2 Vibration

Damped Palletisation (VDP) is based on a polymer in a thin layer

inside the bottom plate of the chuck holding the work piece. The vibrations

in the work piece are being transferred down to the thin polymer where

they are turned into thermo-energy which is easily cooled off via the

bottom plate.

Dot #3 Milling with a VDP-chuck

produces less vibrations and therefore provides a higher surface

quality. This is also extremely time efficient. Independent tests

of VDP have proven as much as 20-40% shorter work time per piece. VDP

also gives four times as long life to the tool's knives, as compared to

when working without VDP.

Material:

The client provided a number of photographs showing their different chuck models

and a lot of documentation on performed tests.

Tools: FreeHand 9 to define the contours of the main image.

After that, the work was moved to Photoshop for perspective, colouring,

surface and shadows.

Click

on the image to return

|