|

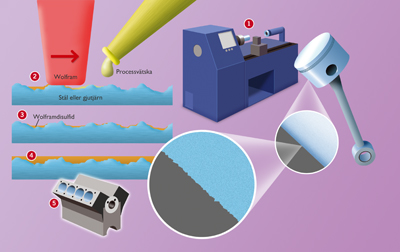

Applied Nano Surfaces has been developing a surfacematerial which can reduce friction at moving engine parts with up to 60%.

1. The material can quite easily be applied using an ordinary lathe. No particul preparation or after treatment is required.

2. E chemical process is achieved when the tungsten surface surface is pressed against the engine part (steel or cast iron) and the process fluid is present.

3. The result is a material which in very thin layers gradually will fill up all the valleys ...

4. ... until the surface is completely smooth. The applied layer is only about 1-2 micrometer thick.

5. It is an economic methode which provides a both durable, environmantally friendly and heat resistant surface. All which have a positive influence on both fuel consumption and mechanical wearing.

Material:

Interview over the phone with a contact person at the company.

Tools: Illustrator to define the outlines. After that the work was moved to Photoshop for colouring, structures and shadows.

Click on any of the images to return

|